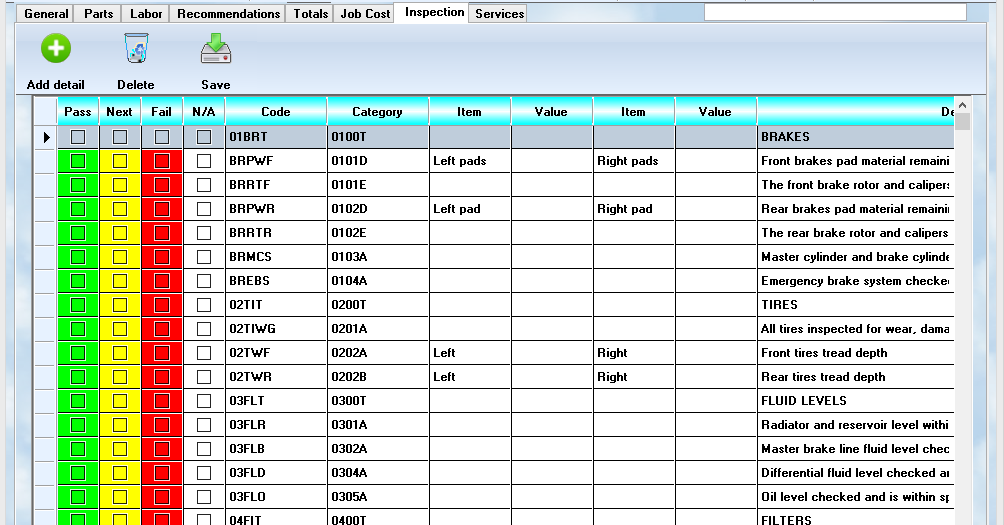

The Checklist displays as a tab on a Workorder. It is easy to apply and use with the following controls:

Basic Controls

Add

When you first click on the tab, there is no checklist available. This is because not every workorder will need one. If you want an inspection checklist for the workorder you have open, click once on the Add button. It may take a few seconds to create the new list. Once you have added it, you will see the list anytime you click on the Inspection tab.

Delete

The Delete button is for individual line items. To remove an item from the checklist, highlight it and click on the Delete button.

Save

Once you have checked off items, and added values, but before switching to another tab, click the Save button. You can work through the entire list if you want, and only click the Save once when you have gone through all items.

Check Lists

To obtain a check mark in a given box, double click your left mouse button while pointing at the desired box.

Pass

Click on the Pass box if the item is currently testing OK.

Next

Click here if the item is within normal limits now, but you believe it may need service at, or before, the next regularly scheduled visit

Fail

Click this box if the item does not meet the manufacturer's specifications and should be serviced immediately.

N/A

Click this box if you do not want the item to appear on the report. Clicking on this box will skip the entry during the printing process.

Values

You can enter values in their respective fields. If the items are setup correctly, the labels will appear next to them. You should also indicate the type of measurement, ie. 45%, 32 mm, 3 qts. Although you could enter data into any values field, it makes more sense to do it when there are labels present.

Printing

When you select the Workorder Print option, you will be asked if you wish to include an inspection checklist. If you say yes, the Checklist will be printed following the other Invoice information. The checklist will be saved in the system and can be reviewed by calling up the workorder from history and viewing / printing it.