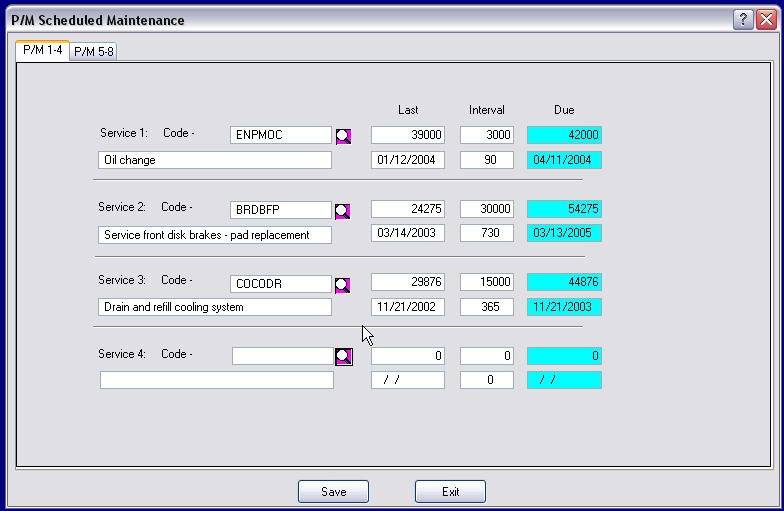

When the P/M option is selected from the workorder button options, the system will display a two page Periodic Maintenance Scheduler IF it has been setup for this service unit. If none has been created, it will ask if you would like to add a table. You can view the pages by selecting the tab at the top of the display. The left tab displays the first four services, and the second tab displays services five through eight.

Code

Each service to be tracked must correspond to a valid Labor Glossary code. The code is entered in the first field of each service display. You must use only codes that currently exist in the Labor Glossary system.

Labor Description

The one line summary description of each service is automatically entered into this field when the Glossary code is first entered.

Mileage / Clock

The first method of tracking recommended services is by usage. This is generally measured by the odometer / clock of the service unit. The first row of figures supplied for each service are based on this method, and applied as listed below.

Date

One method of tracking recommended services is by date intervals, ie. every 3 months. The second row of numbers display the dates when the services should be performed based on the following criterion.

Last

The first tracking column shows the last odometer / clock reading when the specific labor code service was performed, and the date. This is automatically updated by the computer system whenever the service is performed, and is an element of the Daily Closing process.

Interval

This is the amount of days, or miles ( clock hours ) recommended between services. So, if servicing a truck, and oil should be changed every 90 days, or 3000 miles, enter those values in the two fields in this column.

Due

The system will automatically calculate a date, and odometer / clock reading at which the recommended service should take place. This will let you know where the service stands in comparison to the present readings on the service unit.

Working with the client

If a client typically comes in for service every 6,000 miles, and a periodic maintenance is due before that time, be sure to alert the client to the need during the estimate writing discussion time. Then they can decide to obtain the service during the present visit, or return when it is due.

If the notification comes after they have the unit serviced by your facility, they may decide to have the recommended tasks performed somewhere else.

Involve your client Make sure the client is involved in every phase of the service planning. Calling them on the phone later to discuss what is necessary breeds distrust. While it may save time initially, it may lead to frustration and conflict later.