The Glossary system will enable you to add parts and labor to a workorder using simple codes. It is very helpful to build your Glossaries prior to completing many workorders. The on-line manual chapter on the Glossary system will provide detail on how to organize and build these.

Before inputting Glossary items, it is very helpful to create an organization chart. We suggest that you look at the type of product you service. First, consider the "service systems", which are the main maintenance categories. For example, on an automobile, systems might include Brakes, Electrical, Cooling, etc. Next, you divide the systems into "groups". On a vehicle, the brake system might include in the group list front disk brakes, rear disk brakes, rear drum brakes, and master cylinder. Finally, each service group would have a list of specific services performed in that area.

By following this pattern, lookups for services become quite simple. First, the system is selected, then the group, then the specific service. Take your daily work, and divide it into these categories. Then create Glossary descriptions as discussed in the following pages. Specific instructions for each of the areas will be obtained by clicking on the title below:

The parts pick list allows you to add groups of parts to a workorder based on a specific code. You will make up these lists based on the parts numbers in your inventory file which correspond to each item to be included. When you select the parts pick list, or specify one in the kits, ;you will have all of the parts on the list automatically added to the workorder.

Labor glossary codes allow you to enter a detailed description of the service by using a simple code. With the glossary look up list capability, even the most inexperienced service writer can provide the client with a specific description of value.

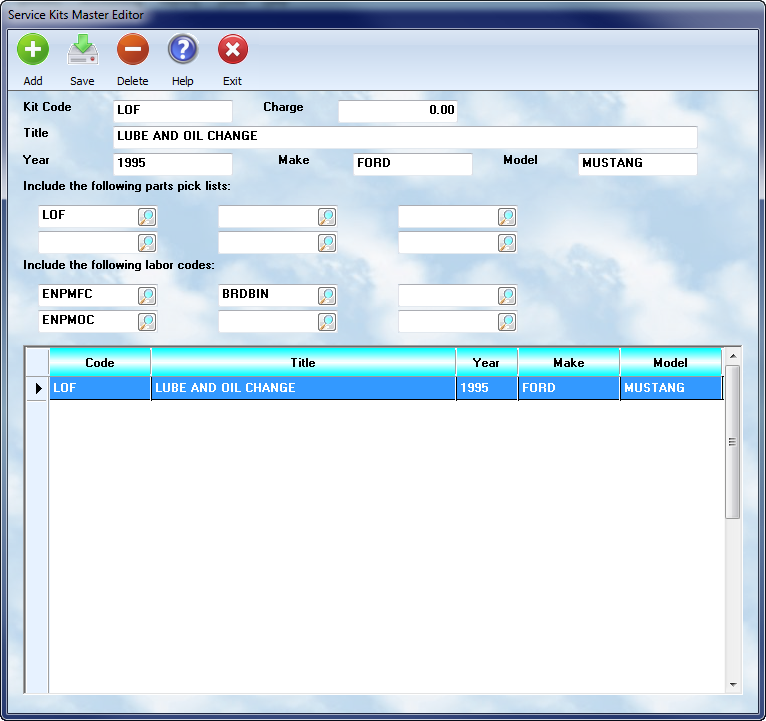

Kits are particularly helpful when handling repetitive maintenance services for vehicles commonly serviced by your business. A kit can have up to six different parts pick lists ( each with multiple parts ) and up to six different labor glossaries ( descriptions ) added to a workorder with a single kit code. Often kits are used when providing periodic maintenance services, ie. a 30,000 mile service.

Your system will maintain a labor chart (history ) for each unique glossary code for vehicles based on year, make, and model. The chart can be rebuilt, or edited, from the Glossary - Chart menu selection. When performing a vehicle service, after entering the glossary code, you can do a lookup on the charge, based on the chart, and see the high, low, and average time and charges you have assessed for that service specific to that vehicle type.