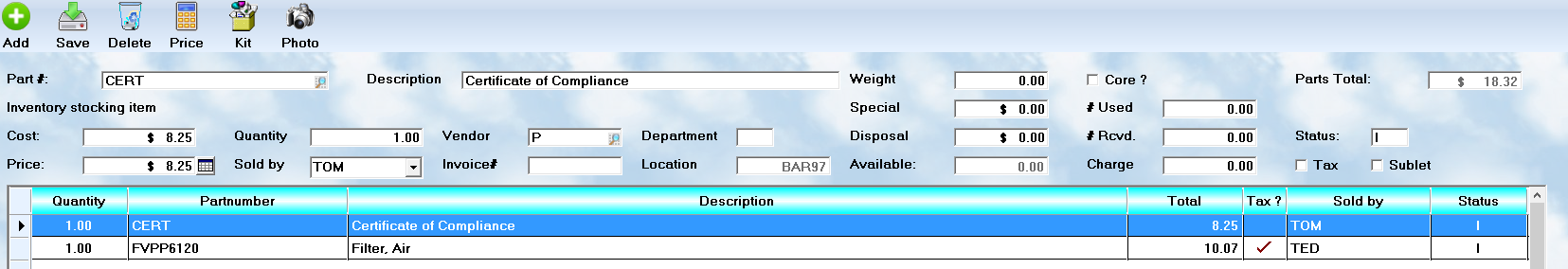

Parts are added using the second tab of the individual wor korder editing window. Important guidelines are detailed below this screen.

Control Buttons

![]() - Use this button to add a new part to the workorder. You must ADD a new record for every part. The quantity will be automatically removed from inventory if it is a stocking part and it will be added to the sales totals.

- Use this button to add a new part to the workorder. You must ADD a new record for every part. The quantity will be automatically removed from inventory if it is a stocking part and it will be added to the sales totals.

![]() - You must press the Save button after entering the informtion on a part. If you find you are missing information it will be because you did not Save it.

- You must press the Save button after entering the informtion on a part. If you find you are missing information it will be because you did not Save it.

![]() - Use this button to remove the highlighted part. This will automatically restock the part in inventory.

- Use this button to remove the highlighted part. This will automatically restock the part in inventory.

If you make a mistake entering a part, use the Delete key to remove the faulty entry and then the Add key to put on the correct part. DO NOT simply change the part number !

![]() - By default, parts entry starts at the Retail level. You can change this to one of the wholesale levels by pressing the Level button and then selecting the desired value.

- By default, parts entry starts at the Retail level. You can change this to one of the wholesale levels by pressing the Level button and then selecting the desired value.

![]() - In the Glossary section, you can create Kits, which are a collection of specific inventory parts items that are used for a service. Please read the description on Kits to see how this can be of significant benefit. Use the Kit button to bring up a listing and search routine for applicable kits. You may select one and all parts will be automatically applied to this workorder.

- In the Glossary section, you can create Kits, which are a collection of specific inventory parts items that are used for a service. Please read the description on Kits to see how this can be of significant benefit. Use the Kit button to bring up a listing and search routine for applicable kits. You may select one and all parts will be automatically applied to this workorder.

You may specify a single price for an entire kit, but we do not recommend this option. The system will place the price in labor, and if you only tax parts in your state, it has no way to know how much tax to assess for the items used in the kit.

![]() View photos attached to this part number.

View photos attached to this part number.

Basic Procedures

Adding A Part

You must first press the Add button to put a record in place to which the information can be written. Then, you may either enter a part number, or select the lookup icon on the right of the part number entry field. The icon will open a search screen that allows you to see all stocking, and non-stocking, parts in your inventory file in either partnumber, or description, order.

It is important that you complete the other information on the screen as appropriate. Of course, your cost should be entered if this is a non-stocking part. Also enter the quantity.

Parts are automatically flagged by the system for tax status but double check to be sure there is a checkmark in the tax box if you want tax charged on this item.

When you add a part to a workorder, the quantity will be deducted from the stocking level, and added to sales totals for the appropriate fields. Even non-stocking parts will have sales totals tracked.

Deleting A Part

Parts are added to the totals in inventory. If you make a mistake, it is imperative that you use the delete key. One common mistake is that people will simply overwrite what is in the fields, or blank it out. This will cause the system to foul. If you delete an item, all totals will be adjusted automatically.

Changing Quantity

If you enter a part on a workorder, and later need to change the quantity, simply change the number in the Quantity box and press the Save key. They system will detect the change and automatically update the totals.

Cores

Some parts will have cores. The computer will properly account for cores if you specify the number used and the number returned. For example, if you have 4 brake pads on a job, you will have 4 cores. If two are damaged beyond usefullness, you will specify the # Used as 4, and the # Ret ( returned ) as 2. Place the amount to be charged for each core in the Charge box and the 2 damaged beyond repair will be assessed on the workorder.

Vendors

The Vendor lookup will allow you to include a specific vendor account for reference purposes on this part. This is especially important when considering the possibility of warranty returns. By indicating the vendor from whom you purchased this item you will be able to process a return easily if the part fails. You can use the PO # field to specify either the purchase order number from your system or the invoice number from the vendor that applies to this part. It is likely that you will not use this option on every part, but certainly it is very useful on all parts costing over a few dollars.

Price Level

The system employs 5 levels of pricing for parts, and 5 for labor. The system defaults to Retail (1) pricing, but this button allows you to select a different level of pricing.

You may add some parts or labor at one price level, and then select a different level for other entries

Deleting Items

If you select the Delete button, and confirm your desire to delete the highlighted entry in the browse screen, the record will be removed from the workorder. Parts from inventory will automatically be returned to stock.

Parts Field Details

You can add parts from your inventory stock, non-stocking parts, or "on the fly" when they are purchased from a local supplier. All methods are done effortlessly, and records are retained for evaluation of your parts profitability. The following information is important on all parts entries.

Part Number

The Auto Shop Writer needs to know the inventory number assigned to the part you intend to use on the workorder. If the part is not in stock, use the number specified when you ordered the part from the vendor. Although some people will use their own "in house" codes, this will lead to confusion, and problems for warranty exchanges. This practice is not recommended.

The Auto Shop Writer supports up to 20 characters in the partnumber. This will exceed any part which we have seen currently available.

Another feature allows you to browse a list by Cross Reference code. (See the Inventory section) The system will ask for the quantity to be sold, and display both the unit, and extended price of all available items. This is especially useful for sales of items such as tires, where the cross reference field can contain the size. By specifying the * before the part number, all available stocking items will be displayed for review in a popup window. By highlighting the desired item, and double clicking the mouse, or pressing the Enter key, the item will be placed upon the workorder.

When entering a special order item, the system will ask if you wish to post it to a purchase order. (See discussion on open PO's in the Inventory references) A Yes response will display a list of open PO's, and when one is highlighted, and selected, the item will be added automatically.

** CRITICAL HINT ** When editing a part, do not change the number. If you need to remove a part, delete the entry. Do not overwrite the existing rectord. If you modify the part number, the computer can not restock the part, nor will it be properly tracked in the summary reports.

Description

Enter a description for the part. Do not use abbreviations - they are poor communicators. If you have requested a part from inventory, this field will be filled in when the part is displayed. It is permissible to modify the description. Some shops will put a vendor code at the end of the description field for warranty purposes. This will remain specific to the workorder, and will not change the inventory listing.

Vendor

The Vendor code field is to be used for the Disbursement Account Number assigned to the vendor by The Auto Shop Writer. For system integrity, these numbers are assigned automatically, and must be used when noting the vendor for a part or labor service item.

It is especially important to note the Vendor because of warranty issues. By reviewing a workorder, you will know exactly which vendor supplied the service item, and who is responsible for its warranty coverage should it fail.

You can look up available vendors by right clicking on the Vendor field using your mouse.

Department

You may assign each part to a specific department. Enter the department code here. You may right click on the mouse for a lookup of the available departments, then highlight the correct entry and left click the mouse, or press Enter, to select the item.

Tax

If the utilized part needs to be taxed, place a checkmark in this box.

Sublet

If the utilized part is part of a sublet service, and was provided by another vendor, check the sublet box.

Core

If this part has a core, place a checkmark in the box.

Quantity

When a part is entered from inventory, the only field not automatically entered is the Quantity. When you enter a value, the computer will calculate the extended price. If everything displayed is correct, press the OK button to accept the entry and add it to the browse list.

The system will alert the user when any parts added to a workorder are out of stock, and permit the user to automatically look at the cross reference list for substitution. If the user opts to not select another part, the item will be added to the workorder, and will cause the stock on hand balance to go below zero. This works well if a part is on order, because when the order is received, and entered into the system, the stock on hand will be correct.

Changing quantity

If you enter an incorrect quantity, simply enter the correct number in the quantity field, and select the OK button. The computer will automatically make the adjustment, either adding or subtracting from stock as appropriate.

Cost

If you enter a part from inventory, the computer will automatically enter the average cost in this field. If you use non-stocking parts, be sure to enter your cost from the vendor's invoice. This will provide accurate profit information when you run the parts utilized report.

Charge

If you enter a part from inventory, the computer will automatically enter the customer's charge in this field. If you use non-stocking parts, be sure to enter the suggested retail price from the vendor's invoice. This is the amount which will be charged on the final invoice, and will be used when calculating your profit when you run the parts utilized report.

Weight

If the part is to be shipped, add the weight in this field. The weight can be assigned to the part in the inventory program, and the value will then be brought forward whenever the part is placed on a workorder.

Special Charge

Some parts have Federal Excise Tax (FET) assessed, or another special tax. If the item entered is such a part, put the amount in this field. Because the charge is specific to the part, rather than the price of the part, it may be entered on the item's inventory listing, and then this value will be provided whenever the part is added to a workorder.

Environment

You may charge clients for the costs involved in disposing of hazardous materials. You should enter the charge in the Environment field.

***CONSIDERATION*** While many people think the environment fee is just the cost paid to some hazardous waste handling company, it should also include costs for any special equipment needed to contain, and process, the parts for disposal. These can be prorated across a normal "lifetime" for the equipment or storage facilities. In addition, you should also include the cost of labor to prepare items for disposal. Consequently, the true cost of disposing of an item may not be the $ .25 the handler chages, but $ .35 which reflects the other costs incurred.

Available

This is the quantity of this part actually in stock when it was withdrawn from inventory. This is used for "auditing"

Location

This shows the inventory location for the part when it was removed from stock. Its inclusion makes it easier for the technician to track down parts when pulling them for the workorder.

Total

This field shows you the running total for the items you have added currently to this workorder.

Core Tracking

Some parts, ie. radiators, brakes, transmissions, have parts with core value. Whenever this is the case, enter a check mark in this field. If the part is in the inventory listing ( stocking or non-stocking ), the core flag will be automatically marked on the part data screen. Non-inventory items will have to be flagged manually.

Core Used

The number of cores used will generally equal the quantity of the part used. Therefore, the system will automatically enter the quantity number in the core used field. In some cases, the manufacturer may track cores differently. For example, brake linings may be tracked as 1 core pair per wheel, or 2 core linings per wheel. Since linings are usually sold in pairs. If the core count is different, it will be necessary to change the Core Used Quantity. If the part has no cores, the quantities are unimportant.

Core Received

Generally, the Core Used number will equal the Core Returned. There are two exceptions. First, on counter sales, the Cores are usually returned at some later time, and processed under the Inventory menu system. The other case occurs when the core is too

damaged to accept for credit. In this case, the Core Returned count would be less than the Core Used. When this occurs, a core charge is added to the invoice, listed under parts. For example, if two linings were installed, but one was damaged, the system would charge for the unusable unit. The Core Used would be 2, while the Core Returned would be 1.

Core Charge

The Core Charge is the amount of money to be charged for all non-returned items. This is set in the inventory data screen, and usually reflects an amount greater than the service center's actual cost (core value). For example, if the manufacturer charges $2.00 for a brake lining core, the service center may charge $2.25. This covers compensation for processing costs for non-returned items.

With non-inventory listing items, this must be entered manually, or the client will not be charged for consumed cores.

Adding the parts

When you add a part, the system will prompt for the partnumber. The cursor will be in the number field. Remember that this is a lookup field. Therefore, you can right click the mouse button to obtain a search window. Alternatively, you can enter a # plus a Pick List code to use a group of parts.

Parts Pick Lists

The Auto Shop Writer Glossary System provides for the creation of Parts Pick Lists. Each list is called by using a code, preceded with the symbol #. The parts are automatically added to the workorder. Since each list can hold up to 50 parts, this

process will certainly speed operations. It is not necessary for parts to be in stocking items in inventory to be on the list, but they should be at least non-stocking items in the listing.

Before entering the parts on the system, the computer will first display the list, and ask if the list is to be edited. If you wish to change quantities, answer Yes and the list will be placed in edit mode. Highlight the items where the quantity is to be changed, and press the Enter key. The computer will then allow you to modify the quantity. If a part is not to be used, simply set the quantity to 0.00. When completed with the editing process, press the OK button to process your entries, and add them to the workorder.

Parts 'On-The-Fly'

If the part is not in inventory, you will need to fill in all of the data listed above. Do not omit information, because that will limit your record keeping and profit analysis. Be very sure to check the tax flag. Once you enter data in all the fields, the computer will add the part to the list, and you will be ready to proceed with your next action.

Editing a part

To edit a part, move the highlight bar to the desired item on the browse list. The part data will appear in the entry box at the top of the screen. Move the cursor to the field you wish to change, then type in your corrections. Select the OK button when you finish, and the changes will be saved. Remember, do not change the partnumber of inventory items.

Changing the Quantity Used

To change the quantity of parts used, highlight the proper part on the browse list, and change the quantity to the newly desired amount. The amount entered is the new total, not the difference between the original entry and that desired. The system will automatically adjust the inventory to account for the change, either removing more from stock, or returning those unused.